Discover the Unique Advantages of Troy Mud Valves

Long Live the Mud Valve!

So reliable it's legendary.

Troy Valve has been manufacturing mud valves for over 25 years. The original Mueller Company design dates back nearly 80 years! Troy Mud Valves stand out in the industry for their exceptional quality and innovative design. Understanding what a mud valve is and what makes it unique is key to recognizing Troy Valve's value to water and wastewater management.

Cast Iron Epoxy Coated Mud Valves

Cast Iron Epoxy Coated Mud Valves

For typical water treatment tanks and basins or industrial spill or overflow containment.

Learn MoreStainless Steel Mud Valves

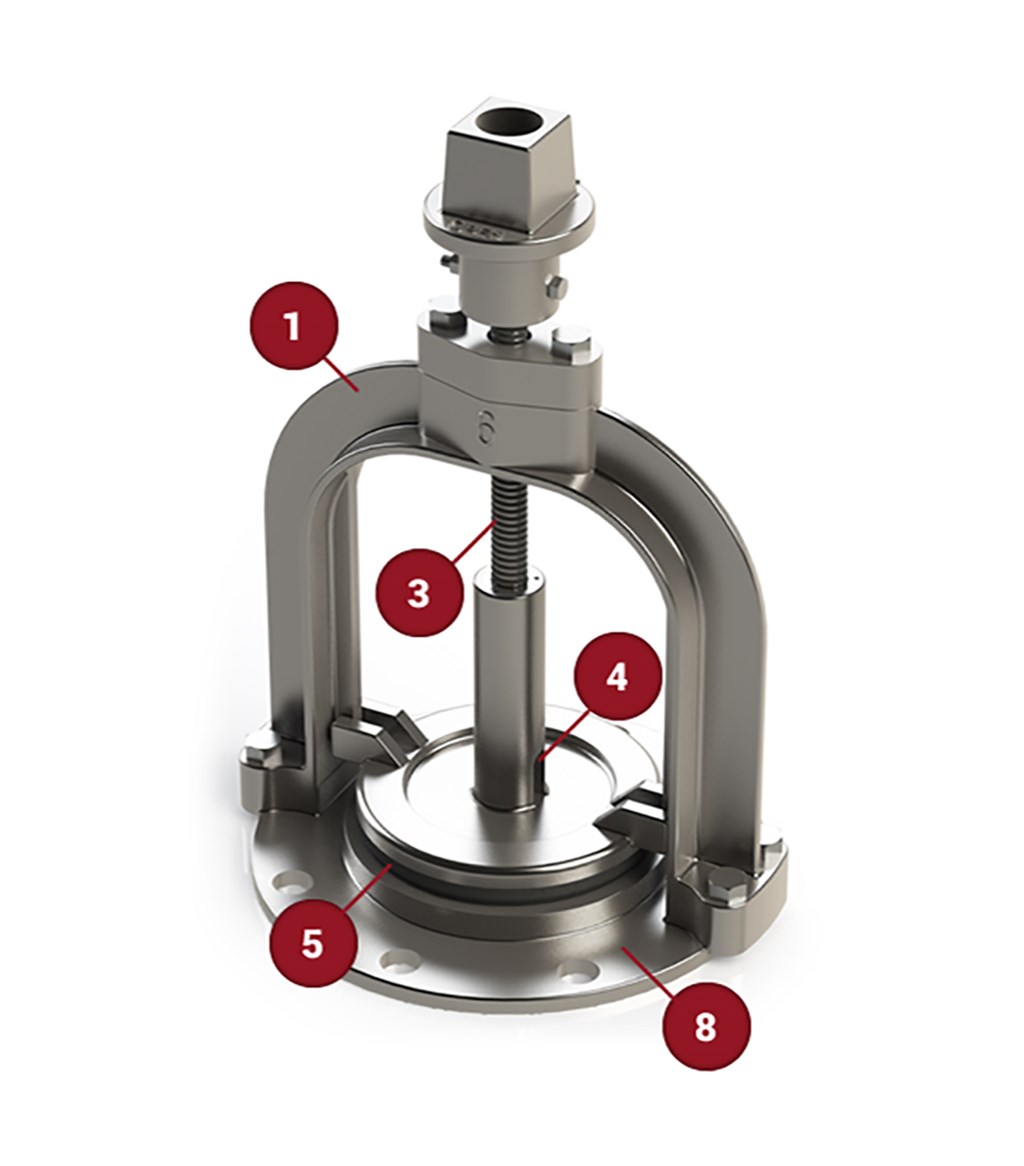

Stainless Steel Mud Valves

For heavy duty uses ranging from very corrosive environments to potable drinking water plants.

Learn MoreMud Valve Operators

Mud Valve Operators

Find all the operator options and accessories you need for opening and closing your mud valve.

Learn MoreThe Dirty Truth

In water and wastewater treatment, the reliability of mud valves is critical. Troy Mud Valves stand out for their durability and efficiency. They ensure reliable performance in demanding environments with a robust design, rigorous in-house quality control, and features like innovative dirty water escape and a bubble-tight seal.

Additionally, their advanced casting process and easy maintenance, including a unique grout pocket feature for complete tank emptying, make them a preferred choice in the industry, where avoiding valve failure is essential.

What Makes a Troy Mud Valve Unique?

Polished design adds structural integrity for longer valve lifetime.

Machining, assembly, paint, testing. It’s all done right here, so we can promise quality through and through.

Designed to make operation easier and reduce actuator size.

Dirty water can wash out and escape the drive area, instead of drying or compacting over time, which can cause thread damage and failure.

Our standard base design creates a bubble-tight seal around common debris, ensuring leak-free operation.

As opposed to older fabrication techniques, our casting process enables our valves to have fewer components and joints, reducing the likelihood of failures.

Configured for easy disassembly in the case of maintenance or replacement.

Unique to our stainless steel design, the grout pocket allows grout to be flush with the drain hole, enabling tanks to empty completely. No other valve on the market has this feature!

You Have A Problem. We Have The Solution.

Confidence