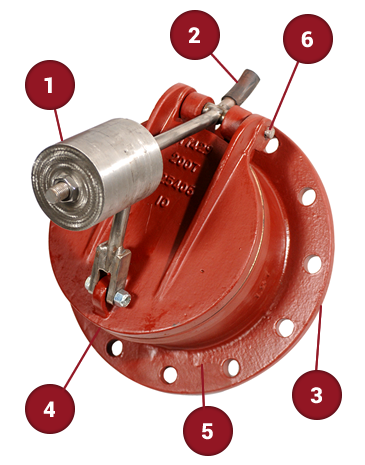

Weighted Flap Valves or Weighted Flap Gates

Be Free of Debris!

Weighted Flap Valves or Weighted Flap Gates, give added resistance to the lid, allowing for the valve to be angled downward (or even upside down) and still have the lid be closed. Under direct pressure the valve will open to allow water to flow out, but closes to prevent debris from entering.

Standard Features

The location of the counterweight on the flap valve can be adjusted to allow flexibility in the field.

To prevent the lid from over-rotating for pump discharge applications, our weighted flap valves incorporate a mechanical stop.

As opposed to fabricated parts, our cast parts have less potential for failure over time.

Our machined seat provides a softer reseating surface because of the extra weight. The 30" to 36" flap valves employ resilient to bronze seating.

Our flap valves have a coating that gives lasting protection against corrosion.

Our valve pins are made of stainless steel so they won’t corrode and bind up the valve.

Operation

When properly installed, the flap valve will swing open under direct pressure to release the outfall fluid and close when the direct pressure is relieved. The Troy Valve A2540 Flap Valve has a 10-degree inclined seating plane to ensure positive seating.

Maintenance

Periodic inspection is recommended to determine that the flap disc remains free to swing open and that the bronze seats have not been damaged.

Installation

Valve must be installed so that the bolt holes in the flange (125-lb. template) straddle the vertical center line. See drawing for diameter and quantity required.

Parts

Parts are available by request. Please contact us for more information.

Weighted Flap Demonstration

You Have A Problem. We Have The Solution.

Confidence