Telescoping Valves for Water Management

Precision Water Level Control with Telescoping Valves

Telescoping valves are engineered for optimal performance in water containment and treatment applications. Our telescopic valves are ideal for maintaining precise water levels in tanks, lagoons, ponds, and water and wastewater plants. Designed to siphon clean water without disturbing sediment, these valves are essential for efficient water management and sediment control.

Rising Telescoping Valves

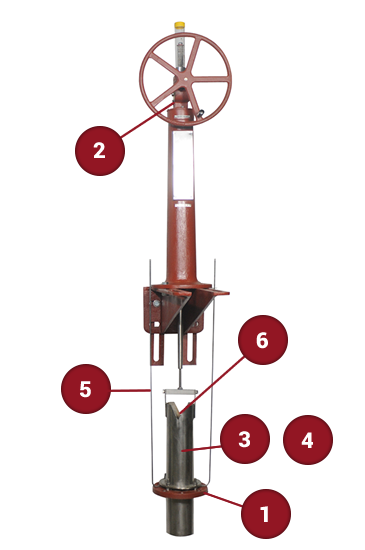

Rising Telescoping Valves

Ideal when gross visual indication is desired or infinite adjustment is needed from a rack and pinion model.

Learn MoreNon-Rising Telescoping Valves

Non-Rising Telescoping Valves

Useful in applications with a low overhead clearance or the need for rapid actuation.

Learn MoreKey Features of Our Telescoping Valves:

Unique gasket design allows simple, fast repair and maintenance without removing slip tube. Seals better than Teflon or Neoprene.

All of our t-valves are self-locking for safety and require no separate locking mechanism. This feature eliminates the possibility of the valve falling if you let go of the hand wheel and the danger of trying to grab the wheel while it is spinning so fast.

Comes with standard 304 stainless steel components and wetted moving parts and standard companion flange with cast iron TNEMEC epoxy coating. Upgrades to 316 stainless steel are available.

Slip tubes are available in all standard pipe sizes up to 30” to best fit your application.

A slip tube lubrication system pumps grease to the slip tube to help keep the companion flange working when routinely exposed to atmosphere. It is also ideal for use in a dry application.

V-notches, scum baffles and weir cones are available, enabling better process control

Customize Your Telescoping Valve

Each telescoping valve from Troy Valve is custom-manufactured to your specifications. To ensure the perfect fit and function for your application, we ask for detailed information at the time of your order, including:

- Floor elevation position

- High water elevation

- Low water elevation

- Flange elevation

- Floor thickness

- Floor type

- Riser/standpipe nominal size

- Pipe material/material requirements

- Space restrictions

Additional considerations that may affect the design of your custom t-valve include:

- Need for the standpipe to be 12" longer than the valve travel

- If low water level is within close proximity to the standpipe flange, a V-Notch may be required, or cones and baffles may not be able to be utilized or modified.

- Larger valves, which have limited travel

- Extra space is needed for the installation of stem guides, which must be placed so they do not interfere between high and low water

- If your application will expose the standpipe flange area to the atmosphere. We offer a grease fitting option for dry applications.

Ready to Optimize Your Water Management System?

If you're facing challenges with water level control, Troy Valve has the solution. Contact us today to discuss your needs and learn more about our telescoping valves.

You Have A Problem. We Have The Solution.

Confidence